Description

This vessel was designed to break up to 2 feet of ice and so the stem and bow plating are appropriately sized. The paint locker/chain locker spaces are furthest forward and are accessed by a sealed deck hatch.

A door in the after bulkhead of the paint locker leads to the chain locker. New wood flooring was fitted to this space at the time of the last docking in Croatia in the spring of 2003.

Moving aft on the foredeck brings you to the anchor/warping windlass. This is a two-cylinder steam engine and permits handling of both anchors as well as providing a rope drum when required. They have used it infrequently as they have had to standby anchor seldom and prefer mooring with lines when in port. However, in the major refit of the vessel in Gdynia Poland in 1991-92 this machine was completely rebuilt with new pistons rods and valves fitted. Most bearings were changed out from Bronze to Thordon SXL. In the 2002/03 lay-up in Varna, Bulgaria, the winch was removed from deck, a double plate added and a new wooden bed fitted.

Slightly forward of the winch is a raised coaming with hatch leading to the Bosun's stores space. This space runs across the breadth of the vessel and is used for storing spare lines, life rings and other supplies.

Immediately in front of the deckhouse is a doghouse skylight structure built of stainless steel by CMN of France. Built to replace a large deck hatch this weather-tight assembly provides ventilation in fair weather to the below deck spaces.

The foremast was built to replace the old unit in 2002/03 and accommodates mountings for radar and many antennae.

The bridge was gutted in 1994 and after insulation, Cherry wood paneling was fitted in narrow vertical strips. The metal of the bridge is armor plate as the vessel was armed in its original configuration. Presumably if you were under attack you could gain protection in this space. A lower level speaking tube port was provided for communication with the engine room when under such conditions.

Only the engine room telegraph, binnacle and helm are original. Tempered glass windows in bronze frames were fitted in Zamdam Holland during the 1995/96 season. These are capable of handling the heaviest seas safely.

The bridge is steam heated and fitted with a Stidd leather helm chair. New solid Oak doors were built and fitted during the winter in Plymouth, England.

The bridge deckhead is narrow strip pine and all cables are bundled and open for maintenance.

Behind the bridge on the upper deck is a bench style seating on both sides of the stack. There is also a stainless steel gas house for propane bottles.

The deck is carpeted and in the aft port corner a spiral staircase leads down to the main deckhouse passageway.

Accommodation

Below the bridge on the main deck are two cabins. The one in the starboard corner is and was the Captain's cabin. All interior furnishings were custom made for the vessel by Canadian Naval Architect/Cabinetmaker Jeff Butt. The Captain's cabin is furnished in mahogany. A standing clothes cabinet with drawer is forward and a matching multi drawer unit is against the fat bulkhead. Beds are bunk configuration with a large one on the bottom and a normal bunk above. Under the bunks are drawers for clothes. Each deck cabin has two portholes. All living spaces are insulated with fiberglass and steam (or electric) heated. Both 220V and 110V power is supplied.

On the port side, the original radio room has become the "office". It includes a single berth which functions normally as a couch seat. There are glass door cabinets for storing all drawings and other technical literature. The interesting advantage of this vessel being built in Soviet times is that there are drawings for virtually every component right down to something as mundane as hinges. If a spare part can't be sourced, it can be made from the dimensioned drawings.

Between the two offices is a companionway leading to the lower deck. It terminates at a vestibule from which four doorways lead to the lower rooms. In the center of the deck is a large spring balanced hatch leading to the lowest space we call the "ammunition locker". This space, which is due to receive all new shelving this season, is where they store technical supplies and provisions. The vessel is equipped with a significant quantity of spare parts. These were a part of the original purchase negotiations. This is the coolest space on board normally and is ventilated by an electric fan discharging to the foredeck through a gooseneck.

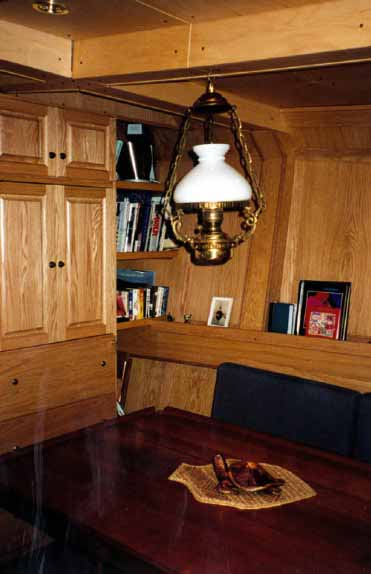

From the vestibule, the space to starboard is the main saloon. All interior woodwork is in Canadian Oak. It includes a small refrigerator, a freezer, a serving table with roll top cover, coffee maker, expresso machine, microwave, etc.

There is a sound system with 4 speakers built into the deckhead, a TV and VCR. Bookshelves and storage under the table bench seating give ample space for navigation charts. There are six large drawers and a small ante-room in the space under the main companionway where racks are set up for literature, samples etc. This room is used for dining, social purposes and for meetings with clients.

Under this room and stretching across the full breadth of the vessel is the main fresh water tank with a capacity of 18 tons.

On the port side is a large cabin. While originally built with 4 bunks, only two have ever been used due to the longevity of the crew.

Forward of this cabin also on the port side is the engineer's cabin. This space has four bunks although normally only three are occupied. There is a closet forward as a separate room.

The guest cabin is on the starboard side opposite the engineer's cabin. It is equipped with one large bunk and it is elevated to take advantage of the broadening hull lines higher up. It also places the bunk in a convenient location relative to the port-light. There are a number of spaces for hanging clothes, drawers and a desk. There is also a hatch through to the foredeck. Forward of the guest cabin is a private bathroom with sink and toilet.

Back on deck, there are three spaces leading aft from the vestibule. On the port side is the toilet room with sink and separate room with toilet. The toilet discharges into a MSA sewage treatment facility.

Mid-ships there is a steel door leading to the "inside passage". This provides safe access along a catwalk to the boiler room and Engine room spaces. In very heavy weather will all exterior doors dogged down this is the only way to move around within the vessel.

On the starboard side aft is the galley. This is fitted with a propane/butane 4 element stove and oven, A large fridge, dishwasher, sink and racks, etc. The galley includes two portholes and a large 3X4 ft. Overhead hatch which adds lots of light and air in fine conditions. Hot and cold water is provided by a pressure electric sanitary pump with steam pump back-up. The water tank is supplanted with a large accumulator on the upper deck. The crew never tested the ultimate capacity of this small galley but suffice it to say it once catered to 27 crew members; the original complement of this class of vessel!

On the portside main deck is a shower room/sauna. This room has of course been re-tiled in ceramic and the walls and deck head are paneled in Canadian cedar. Low-pressure live steam can be admitted to the room or a mixture of hot and cold water for showers.

On the afterdeck is a large steel box with a finished slightly angled tabletop surface. This is used as a serving table and also as a storage cabinet for wood, spares, outboard motors and bicycles. On the upper deck are two 6-man RFD life rafts, and on the main deck an Avon dinghy with a Seagull small motor and a 20HP Mercury motor is available for transit to shore.

Over the top of the rudder quadrant is a raised platform with a wooden lattice varnished oak top surface. This serves as seating space.

Engine Room & Mechanical Equipment

Closed circuit TVs include a bridge monitor allowing viewing of the main engine and rudder machine. This is useful in monitoring the main engine speed and the actions of the engineer in maneuvering. While the vessel has no bowthruster the extraordinary versatility of steam allows maneuvering into spaces that would be impossible with typical diesel single screw propulsion. It requires however a synergy between helmsman and engineer.

In the Engine room a TV monitor allows the engineer a good view of the bridge. There is also a camera looking at the main shaft seal and the smokestack for monitoring of smoke.

A reverse Osmosis unit is fitted in the upper boiler room and is functional but seldom used as bottled water is usually used for drinking and fresh water tanks for boiler water provide ample capacity for clean fresh water.

The boiler room is the largest room on the ship and contains the original welded scotch boiler and various pumps and systems. The boiler was stripped of its asbestos insulation at the time of the major refit in Gdynia. The boiler is in excellent condition and is thoroughly cleaned each season.

Through improvements, fuel consumption has been cut from about 7 TPD when the vessel was bought to less than 4 TPD now. The engine/boiler room is manned by two crew during maneuvering and by one at other times. At sea when set up the attention the plant requires is minimal with a 30 minute walk around with some oiling and inspections.

The boiler room contains a brand new main duplex pressure oil pump, three filters, a trimming/transfer vertical duplex pump and a stand/by high pressure pump. Also included is an electrical pressure fuel pump for starting from cold. The boiler is three fire although in most cruising conditions they run with just two fires lit.

A steam smothering fire system is located in the passageway and essentially blankets the entire engine and boiler rooms with oxygen excluding steam in the event of a fire. There is also an abundance of CO2 and dry powder extinguishers appropriately located.

Steam lines in engine and boiler rooms are still asbestos lagged due to the efficiency of this material but they have all been encapsulated with cotton cloth and sealing compound making them safe and legal.

The vessel current insurance underwrites are not requiring boiler inspections or hydrotests but they do them voluntarily along with annual cleaning.

The original steel deckplates have been replaced with checker surface aluminum.

On both sides of the boiler room are 20 ton fuel tanks. Additionally there is a 40 ton bunker tank under the aft deck together with a separate 20 ton tank for light oil.

Typically the vessel burns 180 cst oil underway and MDO or Gas oil in port. The medium fuel is easier to burn and doesn't require heating, yet the cost is almost the same as for heavy oil. In port we typically light off to raise steam once in a 24 hour day and this is about a 40 minute exercise. If thet are going to be more than two weeks in port they will shut down the main boiler.

The engine room is without doubt the space of most interest and attraction to visitors. It is traditional in most respects yet modern when it comes to safety and efficiency.

The 600 IHP main steam engine is a triple expansion type with Stephenson reverse gear. It is directly connected to the intermediate/tailshaft. There is no clutch and no gears. Switching from ahead to astern is a matter of a few seconds. Max speed for the engine is 160 RPM but it is turning a 2.6m diameter 4 blade stainless steel ice-breaking propeller. They typically rub at 145-150 RPM and that gives a speed of 9.0-9.5 knots with 2 fires lit.

Boiler feed-water is supplied underway by a two-cylinder piston pump driven off a beam, from the high-pressure crosshead. Once the by-pass is adjusted, a good balance is achieved which is sustainable without adjustment for the voyage duration. Also available for feeding the boiler is two vertical duplex steam pumps, and lastly there is an emergency injector. All pumps are lagged with polished sheet copper.

Feed water is fed to the boiler from the hot-well source through a feed water heater. Steam for this heater comes from the auxiliary exhausts. The hot well is replenished as needed from any of the boiler water tanks and boiler chemicals are added by a measured injection from a 20l. poly chemical tank with gravity feed. Inside the hot well are oil-removing screens. Discharge water passes through a duplex oil separator, ensuring only

clean, oil-free water to be delivered to the boiler.

The main condenser is a two-pass shell and tube type with cooling water supplied by a double suction centrifugal pump driven by a single cylinder steam engine. The pump is equipped with Burgmann mechanical shaft seals and is leak-free. Sea water supply is normally from the forward sea chest. This chest is equipped with copper and aluminum anodes charged with 2ma DC current. This Cathelco ionization system is designed to reduce corrosion as well as retard the formation of marine growth. It has proven to be quite effective.

The environmental focus of Thordon Bearings has lead to an interesting way of treating bilge water. Rather than trying to remove oil through a conventional oily water separator (initially tried), we pump the bilge water into an elevated steam heated separation tank. In this tank separation occurs and the water component is pumped over-board. The oily water emulsion is then piped to a Westfallia centrifuge where dirt is removed. The remaining emulsion is then burned in the main boiler.

Due to its size, the Rudokop is not obliged to be fitted with a bilge water separator but this system is practical and functional.

Sanitary water is pumped from the after tank or the forward freshwater tanks by a 24V pumping system forward and through a small RO unit when desired. Also fitted to the upper deck is an accumulator, which adds to the storage capacity. The water is heated either by steam or with an electrical heater.

Engine Room & Mechanical Equipment continued

Aft of the shower/sauna on the portside is the forced draft fan room. In this room is located the single cylinder steam engine which drives the forced draft fan. Air is conducted through a plenum to the air-to-air heat exchanger fitted to the breeching above the furnaces. Combustion gasses pass through the tubes and the forced draft passes the shell before it is directed to the three burner assemblies. Air delivery to each furnace is controllable.

The propeller shaft is carried on two Thordon Compac bearingsand these are supplied with cooling/lubricating water by a Thordon package called a "Water Quality Package" The purpose of this unit is to supply a pressurized source of sea water which has been passed through filters to the stern tube. Included in the package is a flow alarm and horn.

The intermediate shaft bearing is a self-positioning Thordon experimental bearing or SPIB, which contains hydraulic jacks at each corner for the purpose of correctly positioning the bearing. The current bearing is drip oil lubricated but one will be fitted prior to next season, which will have a dedicated sump, and pick-up rings fitted to a cast steel housing.

The Shaft seal is a Thordon SeaThigor mechanical seal. This seal operates leak-free and has run trouble-free for four years so far.

On the after engine room starboard bulkhead is the vertical duplex fire pump. This can double as an emergency bilge pump and can supply fresh or seawater to all fire lines.

As machine shop equipment the engine room area also contains a drill press, lathe/milling machine, grinder, oxy-acetylene welding and cutting gear and electric arc welders.

An air compressor in the engine room provided 7 bar compressed air as needed.

Navigation & Communication Equipment

Communication radios include a SEA 235 HF radio which is currently set up for Sailmail e-mail and voice communications, an ICOM HF tied to our Globe Wireless HF system, a sailor VHF and an ICOM number 2.

There are 4 GPS's on board. One (Trimble) is dedicated to Inmarsat C and the other three are for navigation, primary and back-up. These include two Furuno units and one Lowrance. One GPS is connected to a bridge computer with flat screen monitor, this provides a 17 inch moving map display with a world vector database (Jeppeson Marine Map) in addition to the views shown on two of the GPS's.

A KVH gyrocompass has a primary compass rose display in the bridge and a digital repeater in the Captain's cabin.

Autopilot is Robertson, linked to the gyrocompass. After many teething troubles getting this to work with the steam steering they finally have a system that manages the helm far better than any human ever could before.

Helm position is shown by a mechanical indicator backed up with a Wagner electronic feedback system from the tiller quadrant.

The Furuno Radar was new three years ago and includes ARPA.

A mini-M sat phone is installed and a fax machine is connected.

An anemometer is fitted with a lighted display.

Navigation lighting is original 110 volt with 24VDC back-up. All new non-metallic Perko lights were fitted at the time of the Croatian docking.

Three steam whistles are available for signaling or other purposes. These include the original two chime whistle, a steam siren from a Russian Navy destroyer and a beautiful three chime brass whistle from a Canadian National Railways locomotive. These represent the ship's "voice".

The desk includes monitor and keyboard for the Globe Wireless system. Inmarsat C is our back-up.

The office also contains a fitted Cell phone and the two HF handsets and control heads. There are also two printers, one dedicated to the inmarsat (used mainly for weather) and the other for the main computer. Also a copying machine and supplies of stationery and other office items.

The rudder system comprises a standard rudder supported on three pintles. These are fitted with Thordon SXL bearings and the upper stock bearing is also self-lubricating. The quadrant is driven by a typical chain and rod system. Chain rollers on the afterdeck are greased but equipped with self-lubricating bearings. The main drive sprocket protruding from the Lazarette aft is driven by the original two-cylinder steam steering engine. Input to this engine is from two sources. Manual steering is via a drive shaft from the bridge. Universal joints and right angle gearboxes as needed articulate this driveline.

The autopilot drives the input shaft, which can be de-coupled from the helm by a chain drive system with a 24v electric motor. Rudder position feedback comes from sensing the position of the output shaft from the steam steering engine. In spite of a great deal of difficulty in setting it up this system works flawlessly and the autopilot steers a better course than our best helmsman.

At sea they operate with one person on the bridge and a second as watchman at night while in the engine room there is just one engineer on watch. Essentially, two people other than in maneuvering situations can easily man the vessel. In port entry and departure we will put a fireman in the boiler room and two deckhands to manage lines.

Electrical System

5 different power supplies available. 12 and 24 VDC, 110 VAC, (50 Hz), 220VAC, and 380 VAC three phase.

Electrical power on board is furnished by a Lister 3 cylinder 15kw gen set producing 220vAC Because so many services normally requiring electric power are on the Rudokop served by steam, the electrical load is small for a ship of this size and 15kw is quite enough capacity.

As a back up there is theoriginal steam gen set, slightly modified for efficiency. The direct driven 110V DC generator is gone and in its place is a belt driven alternator producing 25kw of power in 3-phase 380V form.

The main isolation transformer can convert this power to 110V AC or 220VAC as required and is wound for any shore-side input.

Also fitted is amotor/generator unit capable of providing 380/3 power should only 220v shore power be available.

Sixteen truck batteries in a battery box on the upper deck furnish DC power. Both 24v and 12 V are available and a battery charger constantly keeps these batteries in shape. The batteries are replaced every 5 years.

Remarks

She was designed to be seagoing and the Captain has had her in force ten conditions. This is not pleasant sailing but the vessel is up to it and handles well. Bilge keels were added in 1995 to reduce roll. The schedules demanded that the Captain has the vessel in each of a series of ports to accommodate planned customer visits. They sail therefore in conditions that would confine a normal yacht to port.

The ship handling skills needed to manage Rudokop in port need to be learned. With no thrusters and a single large wheel she is demanding but once the skills are mastered and the communication between engineer and helmsman established, the berthing procedures become enjoyable. The vessel is vibration and noise-free, and a delight to handle.

Exclusions

A detailed inventory list of exclusions of Owner's personal effects and artwork will be provided pursuant to a purchase agreement.